Questa ricerca permette di trovare il modello di forno standard in base ai parametri immessi dal cliente (materiale, lavorazioni, accessori, ecc...)

Questa ricerca permette di trovare il modello di forno ricercando qualsiasi termine all'interno dei titoli, delle descrizioni e delle caratteristiche

S.M. series Used & Overhauled Furnaces

S.Q. series Used & Overhauled Furnaces

S.O. series Used & Overhauled Furnaces

Accessories - Feeding Systems

Accessories - Manipulator

Accessories - Soundproofing Cabins

S.M. series Used & Overhauled Furnaces

Availability of a huge number of optionals for specific production needs.

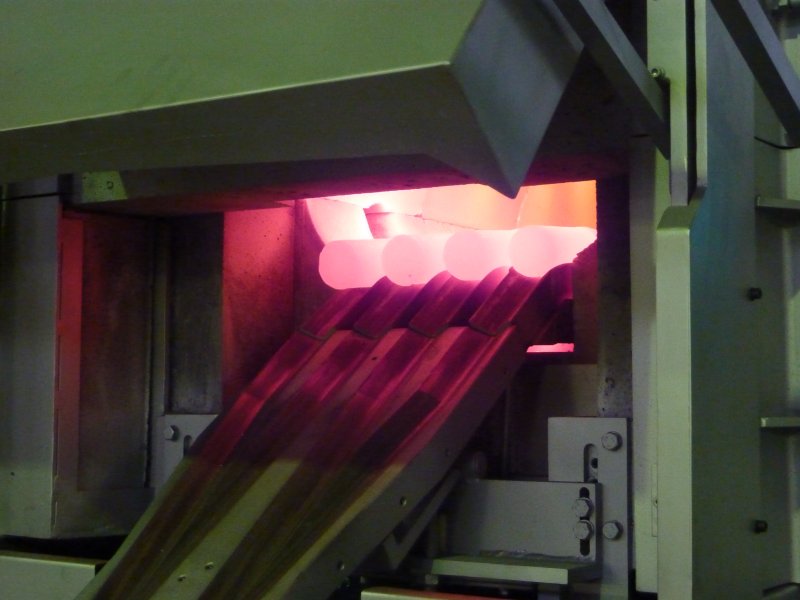

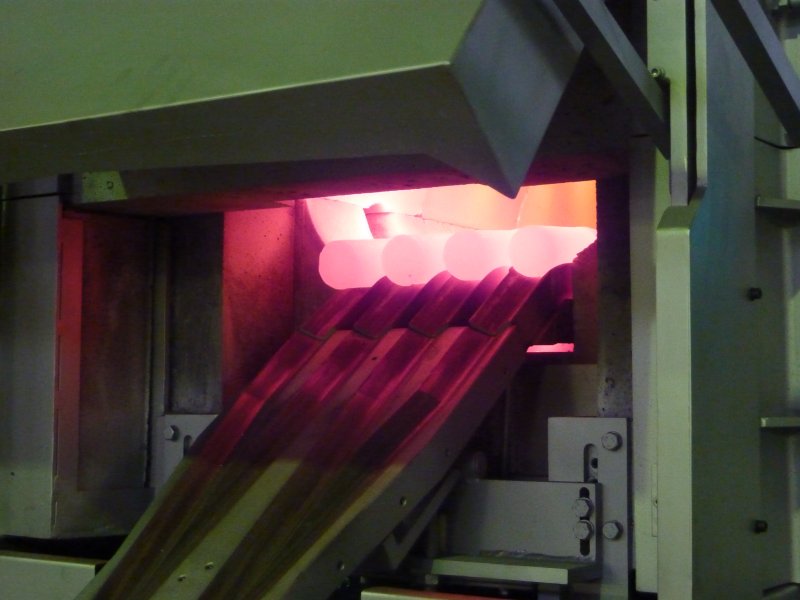

Temperature regulation by proportional modulating action, allowing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple for entrance and central zones; by optical pyrometer for the exit zone. Direct heating by burner on the heating chamber vault and flame on tacks.

Trac stand on steel rods, not directly on refractory; these determines a more uniform heat transfer on tracks less oxidation of the parts, preservation of graphite features (if used), less bending and longer las

Four combustion chamber lengths are available: SM 210, SM260 (2 zones) and SM320, SM380 (3 zones), where the model number indicates length in mm. The chamber is provided with 3 tracks having 120 mm wheelbase (pieces diam. 25-100 mm) or 4 tracks having wheelbase 80 mm (pieces diam. 25-60 mm).

Feeder/In-column device AGS (pieces L:150), AGL (pieces L.300).

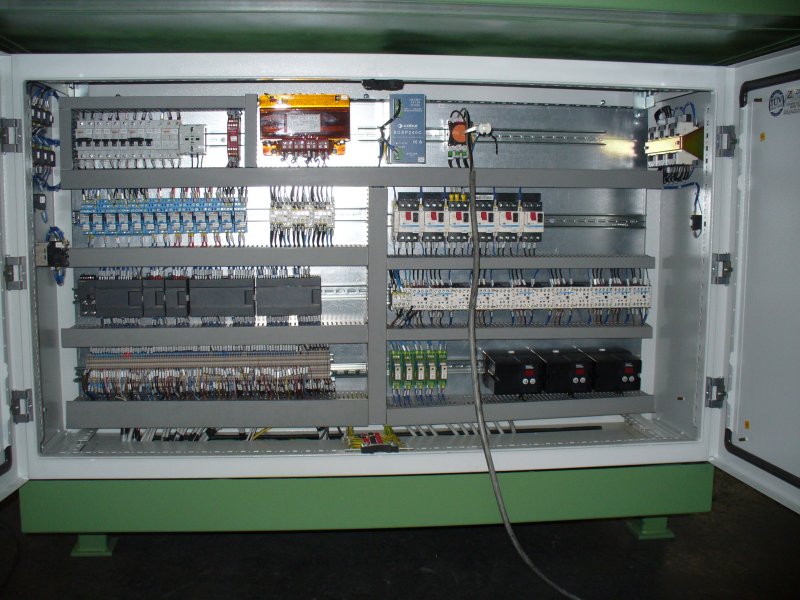

Electrical switchboard and operator panel, both aide the machine included. Feed logics by PLC.

Temperature regulation by microchip thermoregulator.

S.Q. series Used & Overhauled Furnaces

Availability of a wide number of optionals for specific production needs.

Temperature regulation by proportional modulating action, allowing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple for entrance and central zones; by optical pyrometer for the exit zone. Direct heating by burners on the heating chamber vault and flame on tracks.

Tracks stand on steel rods, not directly on refractory, these determines a more uniform heat transfer on tracks: less oxidant of the parts, preservation of graphite features (if used) less bending and longer lasting of tracks, easiness in cleaning the heating chamber hearth.

Four chamber length are available: SQ180, SQ240, SQ300, SQ360 (all 2 zones), where model number indicates length in mm. Every chamber can be provided by racks, having wheelbase 50mm.

Feeder/In-column device AC (pieces L.100), AS (pieces L.150), AL (pieces L.300).

Electrical switchboard and operator panel, both beside the machine, included. Feed logics by PLC.

S.O. series Used & Overhauled Furnaces

Present on the market since 1984, these were improved time by time and distinguish for the very high number of installations and trials.

Temperature regulation by proportional modulating action, allowing temperature uniformity to be +/- 0.5% of preset value. Check up by thermocouple on one or two zones, according to heating chamber length.

Direct heating by burners on the heating chamber vault and flame on tracks.

In 2G version, tracks wheelbase is 80 mm (pieces diam. 15-60mm) or 120 mm (pieces diam. 15-80), in 3G version, the wheelbase is 75 mm (pieces diam. 15-60 mm).

Four combustion chamber lengths are available: SO180, SO240 (1 zone) e SO240, SO300, SO360 (2 zones), where the model number indicates length in mm. The chamber is provided with 2 or 3 tracks according to required production and parts to be heated.

Feeder/In-column device AC (pieces L.100), As (pieces L.150), AL 8pieces L. 300).

Electrical switchboard and operator panel beside the machine included. Feed logics by electromechanical relays.

Temperature regulation by microchip thermoregulator.

Accessories - Feeding Systems

Accessories - Soundproofing Cabins

Robust structure, suitable for required acoustic insulation.

Built up according to laws in force.

Ricerca contestuale:

Ricerca per termine:

No product matches your request.

S.M. series furnaces.

S.M. furnace completes the series range and distinguish for its high thermal power, to ensure very high hourly production along with maximum heating quality.

Designed to feed new generation press machines for automatic forging on one, two, of four figures.

These distinguish for their extreme use versatility, and conduction simplicity. Designed to allow maximum productivity with minimum overall dimension, these solve more and more present needs of limitation in available room with increased quantity produced.These are suitable for precision heating of huge quantity fo small, medium and large parts (maximum weight 5 kilos/parts).

S.Q. series furnaces:

Exclusively produced in 4 tracks version, S.Q. furnaces are designed to allow high productivity also in presence of extremely limited room available.

The evolution trend in hot forging has stimulated perfectioning of quality features of furnaces in terms of temperature uniformity and production velocity. The answer to these requirements is realized by this series of furnaces thanks to the use of sophisticated temperature detection and regulation systems.

S.O series furnaces

Great use versatility, functionality and reliability the main features for a wide and diversificated range, designed for forging a single piece or two pieces simultaneously.

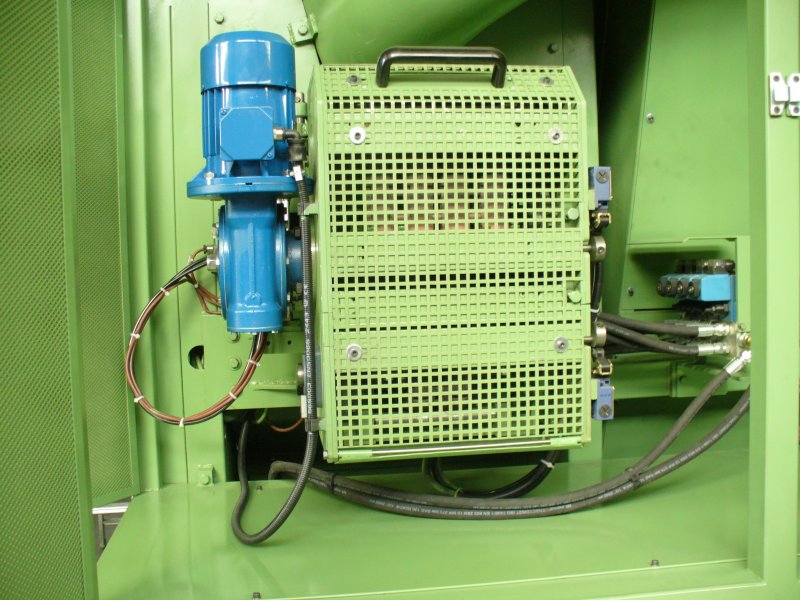

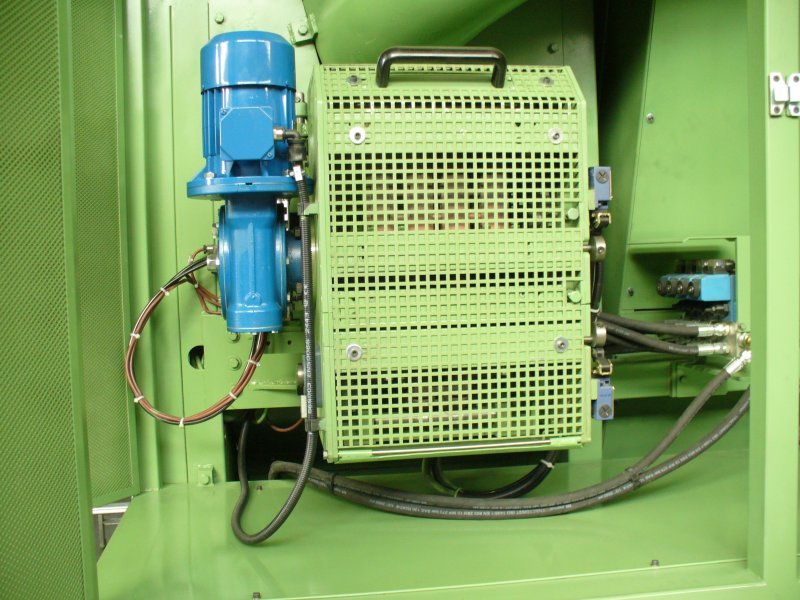

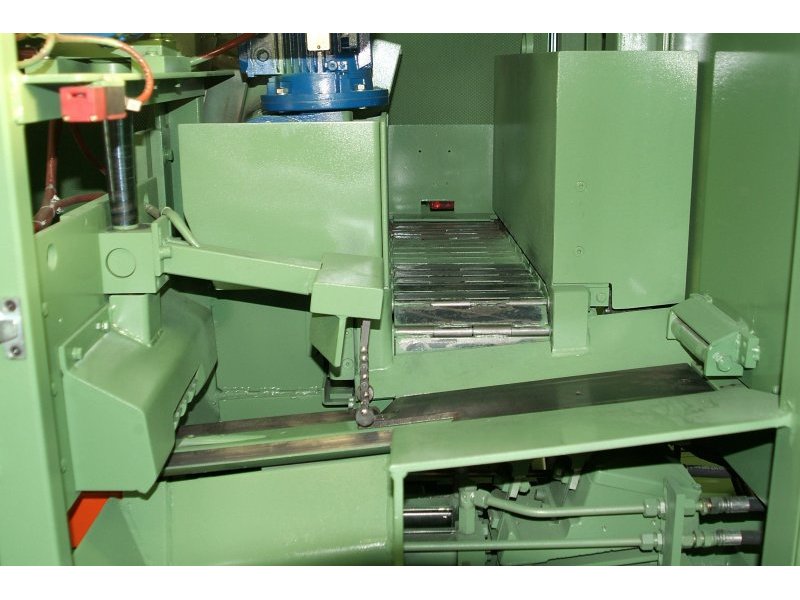

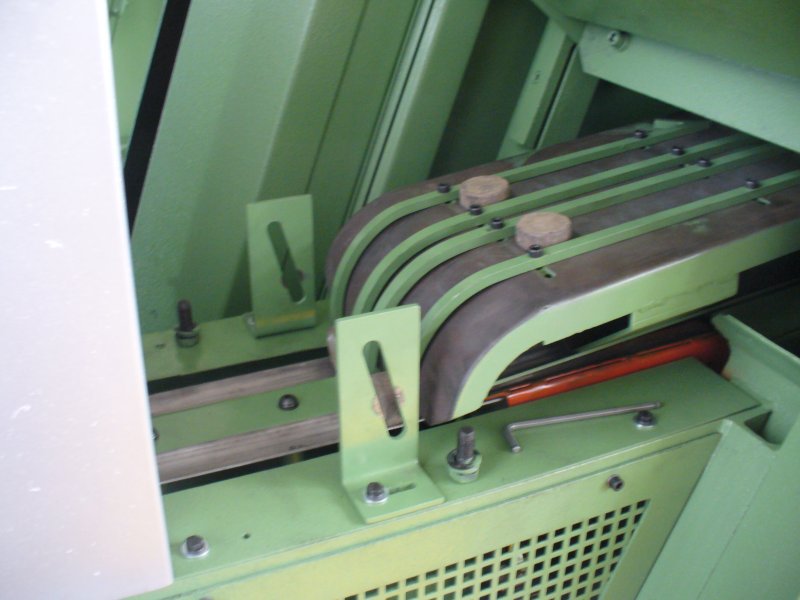

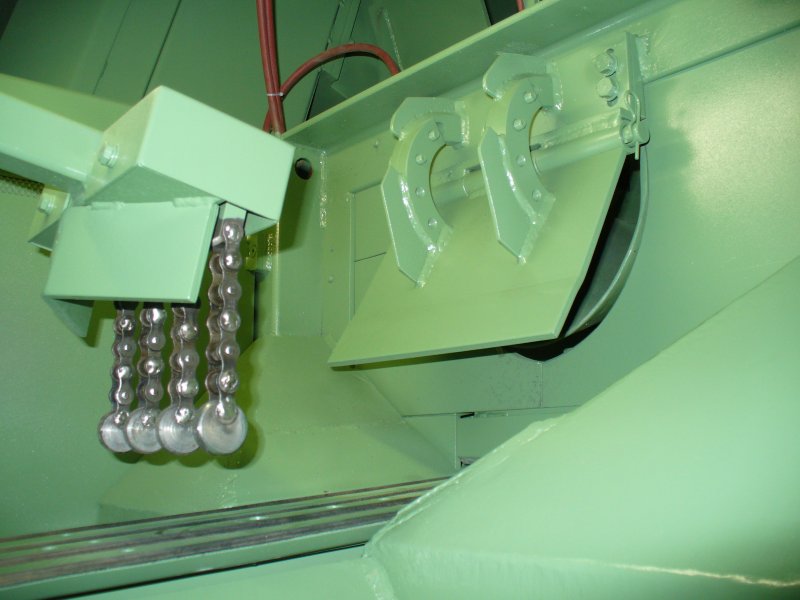

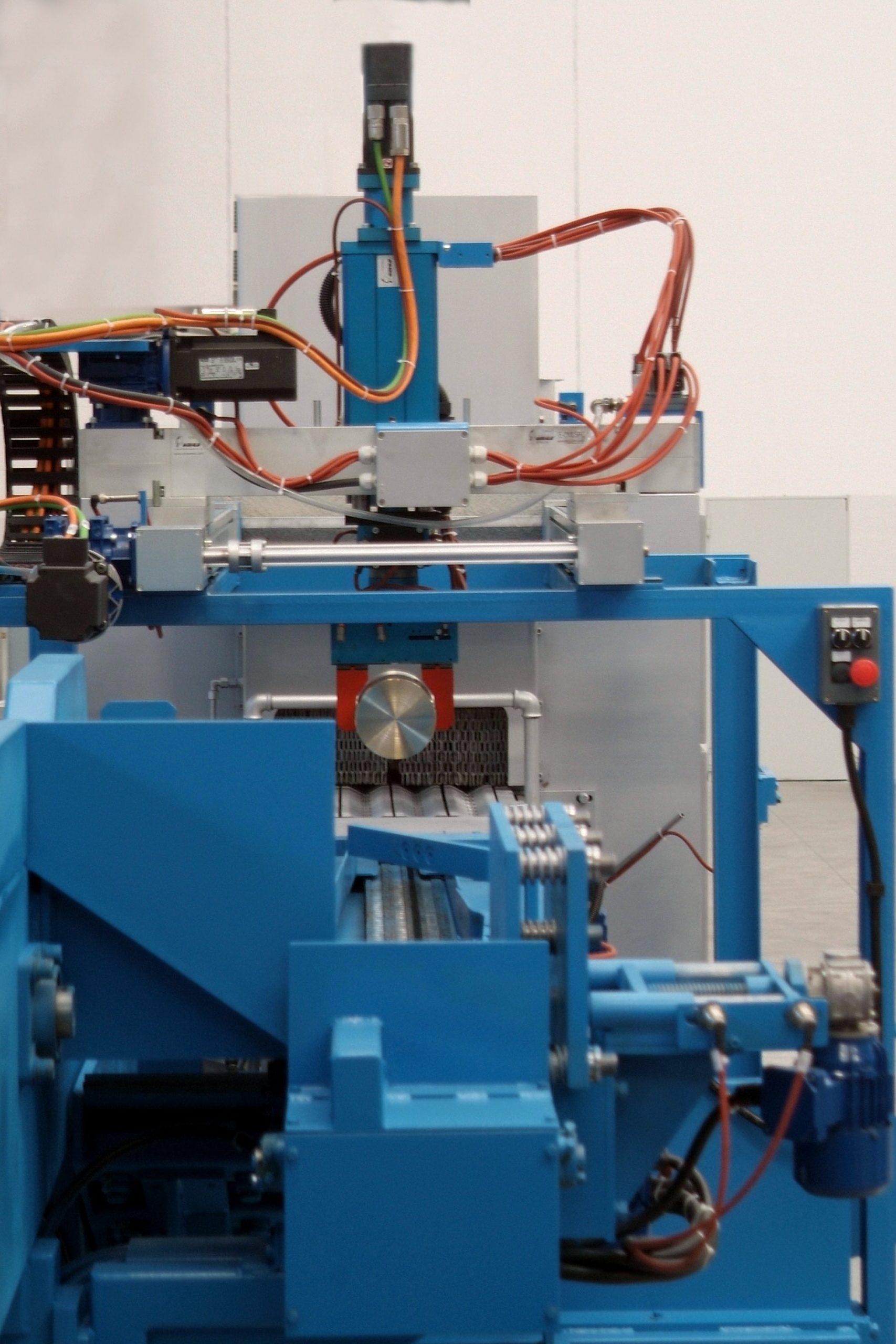

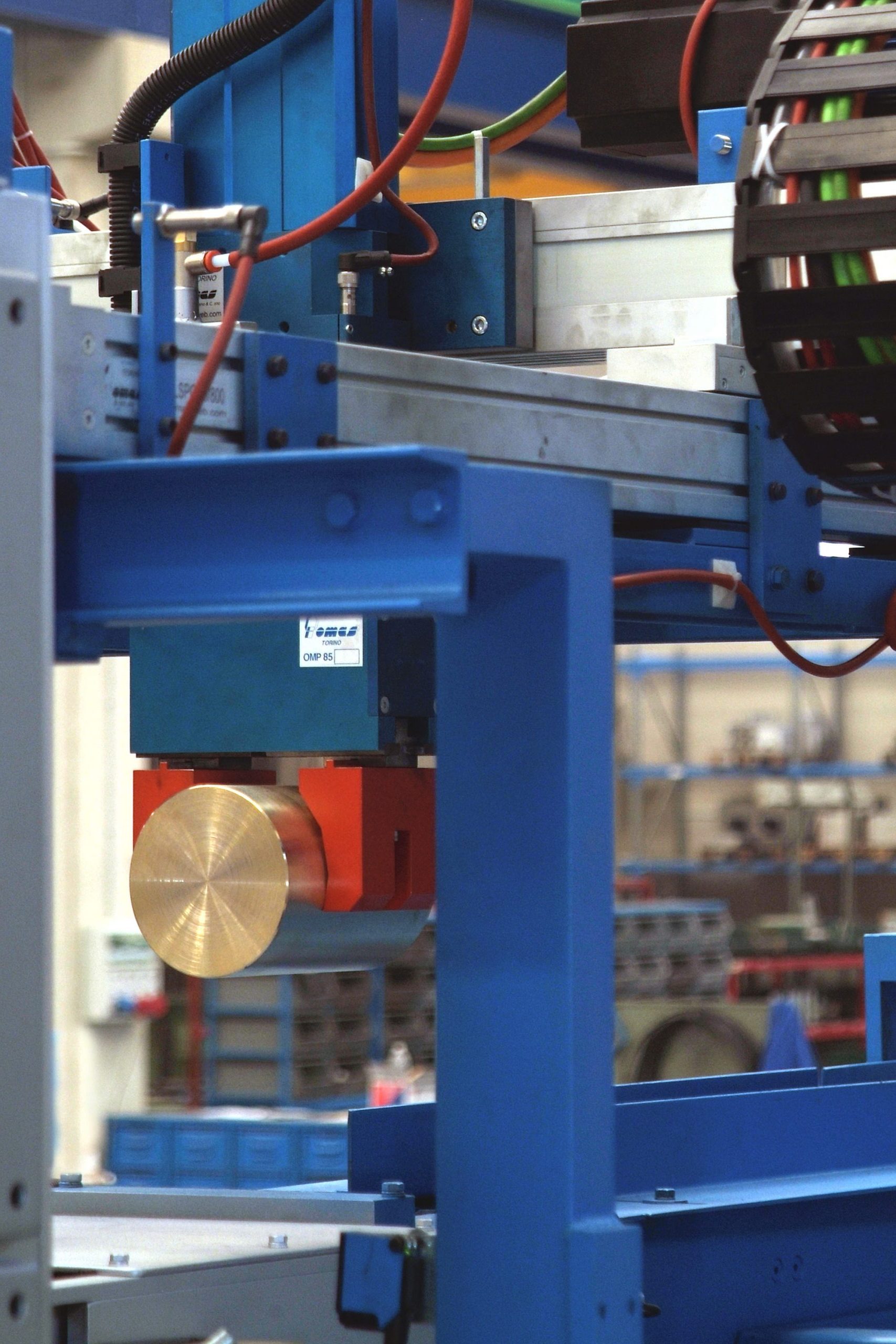

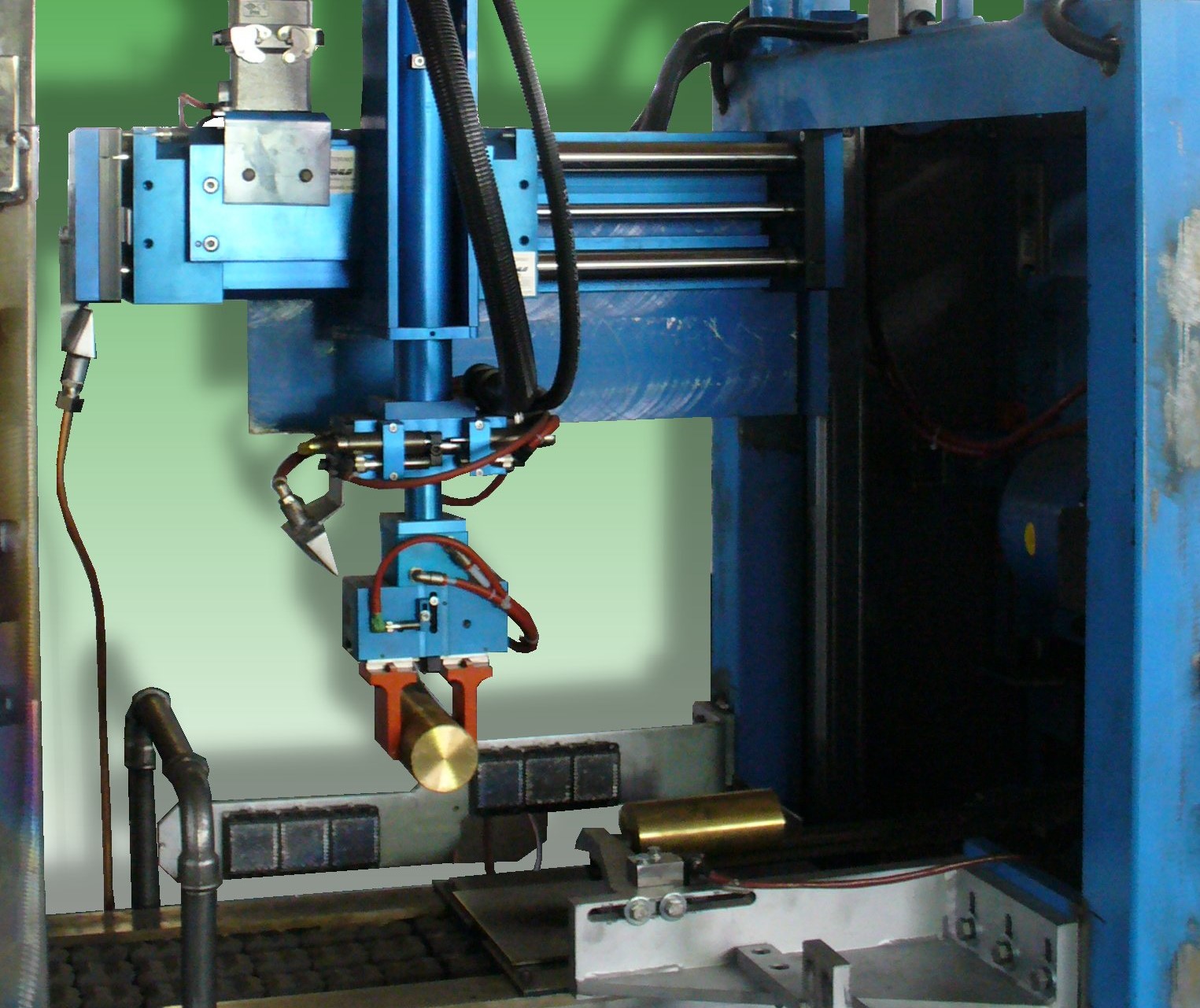

Farm brass feeding systems are normally mounted on the machine but, in case of special needs, it is possible to separate the entire power supply unit / clamping unit to be able to interfere with particular machinery. Farm brass power supplies can be supplied with vibration technology or conveyor belt based on casting pieces.

Sturdy structure that is appropriate to the weight of the moving parts

Punching device pieces from a four columns

Moved in automatic billets, disks or paintings

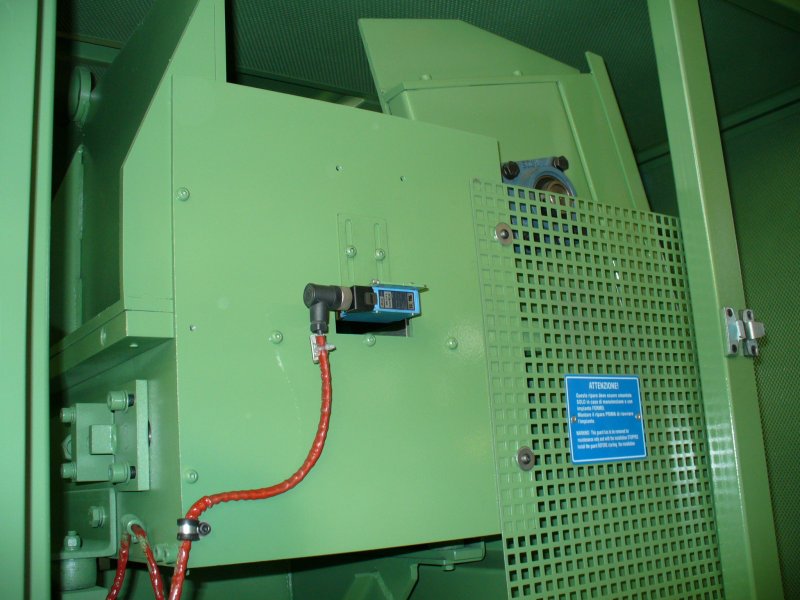

Soundproof cabins for feeding systems

Farm brass’ soundproof cabins are norm ally assembled beside the machine but, in case of particular needs, in is possible to separate the entire group, creating a perimeter soundproof protection, tailor-made for the machine.